Automatic double side square bottle labeling machine

Automatic double side square bottle labeling machine for bottles is design to handle a wide range of self-adhesive labelling applications with speed and accuracy in either single, twin or tri-labelling head configuration can apply front, back, partial wrap or full wrap labels as well as tamper evident or promotional top labels. Two label dispensers operates independently for one side labeling or operate simultaneously for two side labeling which allows different size of label application on either side, An optional wrap station is offered for partial wrap or full wrap labels as well as tamper evident or promotional top labels. Front and Back sticker labeler machine is equipped with a chain aligner system for product orientation, ensuring correct positioning of the containers before the label is applied. The container position is adjusted by the spring mounted motorized chains before it moves under the head gripper where it is released. The head gripper is mounted on a vertical stainless steel spindle system for easy adjustment when needed. Additional features includes stainless steel construction and anodize components, world famous electronic components, servo motor drive, powered assist web take up, PLC control and user friendly HMI.

Key Features

1.Heavy-duty stainless steel constructed anodized aluminium components

2.Electronic components are world famous brand

3.Capable of labeling flat,oval,square and round containers

4.Variable speed bottle infeed seperator wheel

5.PLC control and user friendly HMI

6.Servo motor drive delivers accurate and high-speed repeatable labeling

7.Top stabilizing/conveyor belt is provided to hold the bottle for proper labeling.

8.Automatic synchronized label head and conveyor belt

9.Power assisted web take up

10.Low or missing label detection with automatic stop system to prevent mislabeling

11.Non-contact photo eye sensors

12.Label counter

Available Options

1.Hot stamp printing coder with base (prints characters directly onto the label)

2.Clear Label Sensors (capable of detecting transparent labels)

3.Wraparound station

Technical Specifications

Direction | Left to Right or Right to Left | ||

Speed | 120-250CPM(Depending on product characteristics and feed speed) | ||

Container Diameter | 25-120mm | ||

Container Height | 55-400mm | ||

Label Length | 15-300mm | ||

Label Height | 10-150mm | ||

Labeling Accuracy | ±0.5mm(Subject to product characteristics) | ||

Label Reel Size | 320mm(Max) | ||

Label Core Size | 76mm | ||

Electric Supply | 110/220V 50/60HZ 1PH 950W | ||

Weight | 350KG | ||

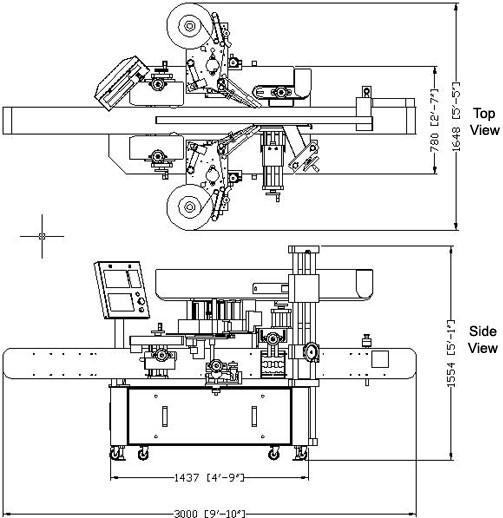

Dimension | 2800x1450x1500mm | ||

specifications can be changed as per customer requirements | |||

About us

Our company is a leading developer and manufacturer of complete turnkey liquid packaging solution of designing, manufacturing, installing and training. Our professional engineer team will design and manufacture machines according to your specific product characters, budget and other factors. Our factory is ISO and CE certified to ensure the highest standard in the industry are met.

We offer a variety of washing machine,filling machines including monoblock rinsing filling capping machines, piston filling machines, corrosive filling machines, gravity filling machine, monoblock fill plug capping machines, capping machine are including semi automatic capping machines, automatic inline spindle capping machines and rotary capping machines, induction sealing machine, vacuum capping machine. labeling machines including shrink sleeve labeling machines and self-adhesive labeling machines. We provide one stop filling and packaging equipment in design, manufacturing, installation and training.

Our machines are widely used in beverages, food, household products, personal care products, chemicals etc. How to choose a right equipment is big challenge for startup or some customers who want to expand his business. It depends on many factors including liquid characters, container shape and size, cap geometry and size, speed etc. Monoblock rinsing filling capping machines are designed for water, carbonated soft drinks, juice, beverage, tea, milk and yogurt, gravity filling machine is suited for free flowing thin liquid, piston filling machine is best for thick liquids with or without particulates, corrosive liquid filling machine is specially designed to fill corrosive liquids, monoblock fill plug cap machine is ideal solution for vials and small bottles.

We committed to providing good service before, during, and after the sale, and feel that all questions and concerns deserve an expedited answer. Our goal is to provide you the best performance machinery, at the best price, with the shortest delivery date. Customer first is our principle, we would like to grow and develop with our customers whether you are startup company or big company, always with you forever.

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic.

4.Our promise

One Year Warranty On All Equipment,Three Year Guarantee Stainless Steel And jackets,Prouclly Designed And Engineered In our factory,Proven Experience And Liong-term support,Customize Equipment To Fit Your need.

5. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.