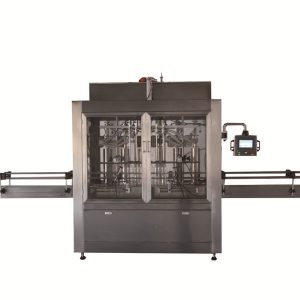

Edible Oil Bottle Filling Machine

Consumable oil products such as coconut and peanut oils require different types of edible oil filling equipment based on their thickness. NPACK carries plenty of liquid packaging machines intended for packaging edible oils and many other water-thin to more viscous liquid products. We offer a variety of filling machines along with other equipment such as conveyors, cappers, and labelers to form a complete packaging assembly that offers consistent efficiency.

This filling machine is specially made for all materials, such as water, gel, shampoo, oil olive oil,motor oil etc. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill manykinds of the bottles in one filling machine, with quick speed and high precision. The machine can fill differentshapes of bottle such as circular, round, flat, square, etc. It is suitable for glass bottle and plastic bottle.The filling capacity can be adjustable, the filling volume can be varied from 500-2500 ml by adjusting the piston pump.

An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen.

Our advantages:

- We provide our customers with all components for free within 1 year.

- We offer long life maintenance, technical support is available, offer videos of installation and debugging.

- Our machine is easy for installation. We will take pictures of the disconnect parts of machines, youcan install the machines according to pictures. We attach marks on the machines that need to connect,you caninstall the machines by yourselves. It is cost saving for you.

- The spare parts are optional according to customers needs.

- The handle of the machine can be freely and conveniently turned to adjust so that various types ofbottles can be used.

Install a system of edible oil filling equipment

Vegetable oils and other consumable oil products can vary in viscosity, which means that different edible oil filling machines are required depending on the application. To meet the needs of various edible oil production lines, we offer piston, gravity, overflow, pressure, and pump fillers to keep the filling process accurate and efficient.

To complete the packaging process, we offer a selection of other liquid packaging machinery that’s compatible with consumable oil products, including customizable systems of bottle cleaners, conveyors, labelers, and cappers. Each machine in our inventory is designed to maximize productivity in packaging facilities.

Use high-quality cooking & vegetable oil filling machines with many configurations

Like other types of packaging systems, you can fully customize cooking oil filling machines and other edible oil machines based on the needs of your specific application. Specifications may be based on the viscosity of the product and space requirements in the facility, all of which NPACK can meet. Our reliable food oil machines can help keep your facility efficient while making sure your production lines are as profitable as they can be. No part of your food oil packing systems will remain overlooked with a full system installed to keep your operations optimal.

Features:

- It is applicable to different shaped bottles and plastic bottles: plastic,glass bottle and mould bottle. The bottle – in and bottle- out has specialized structure. It doesn’t drop bottles or nip bottles.

- Suitable filling material: This machine adopts piston pump, which is suitable for all kind materials, with highfilling speed and high filling precision.

- For filling corrosive, the position pump will be made by silicon rubber, Teflon, ceramics and other corrosion resistance materials.

- Controlling system: The machine adopts full-auto PLC and human-computer touch screen control system.

- For different volumes adjustment, we set several procedures, mode 1, mode 2, mode 3“` Operators do not need too much complicated adjustments, the filling machine can switch betweenthe three models easily.

- Different volume adjustment: By adjusting the piston pump, it also can fill all the liquid from 500-2500ml.

- Bottle position correct device:To ensure the bottles and filling nozzles are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable.

- No bottle no filling:Filling nozzles. The filling nozzles are specialized made: anti drop. Also, the filling nozzles will come into the bottle bottom, and moving up slowly when filling.

- Cleaning: The pump uses quick-fit removal Structure, it is easy cleaning and disinfection.

Incorporating complete oil packaging machine systems

If you want more than edible oil filling equipment installed in your production line, we have the equipment you need to make your entire assembly more reliable.

Before the filling process, our bottle cleaners can make sure that containers are free of any potential contaminants including harmful bacteria. After filling equipment accurately fills containers, capping machines can attach airtight caps of different shapes and sizes to custom-sized bottles, and labelers can place high-quality labels containing images and text that display product information and brands. A system of conveyors transports products between stations at consistent speeds, making sure each product is filled and packaged within the designated amount of time for maximum profitability.

Get a custom oil packaging system design at NPACK

To meet your application’s specific needs regarding space requirements and product specifications, we can help with the design of a complete packaging system for your facility. To make sure that equipment is implemented properly in your facility, we also offer installation services. Our experts can install equipment at nearly any location in the u.s.

Our technical experts are also capable of maximizing the effectiveness of your packaging system by providing field service, high-speed camera services, and leasing. Each of these services can improve the overall performance of your machinery along with operator productivity.

If you would like to get started on the design and setup of a complete system of edible oil filling equipment and other packaging machines, contact NPACK for immediate assistance.