Description of automatic liquid bottle filling machine:

This machine is mainly available to fill your square bottle and round bottle.

The filling machine adopts double-headed 316L Stainless steel piston pumps quantitative filling . It is easy to clean. It is able to wear and tear. There is have O-ring and seal gasket in the pump, so there is no impurity, and do not pollute the liquid. Besides, the filling precision of this pump is high. And touch screen controls all action.

After filling into sucked inner plug, cover, by pneumatic control, robot- hand plugger,cover. Then into capping, this capping parts use the transverse torque and automatic slipping unit. So it does not hurt the cover. The bottles don’t follow with the capping head, the turntable does not hurt the bottle, so the design protects the beautiful of the packaging material.

No bottle no filling and no capping. If there is no plug in the bottle, it must not cap until having been detected plug in the bottle. The machine enjoys high position accuracy, stable driving, precise dosage, and simple operation and also protects bottle caps

automatic straight line high precision metering pump filling machine, this machine is straight line filling machine. It is suitable for filling oil filling machine with round glass bottles and plastic bottles of various shapes. Filling principle is through the touch screen to set the PLC filling volume and filling speed, after conversion of PLC pulse number and pulse rate are sent to the stepper motor drive, drive after receiving pulse stepper motor according to the touch screen set to drive high precision gear pump to achieve filling process.

The filling amount set by the touch screen is controlled by the number of revolutions of the gear pump driven by the stepping motor. The filling speed set by the touch screen is controlled by the speed of the gear pump driven by the stepping motor. After a small number of parts are replaced and appropriate adjustments are made, glass and plastic bottles of different heights and diameters can be filled.

This machine is applicable to cooking oil ,lube oil,essential oil,coconut oil,vegetable oil,olive oil,palm oil,peanut oil,engine oil,soybean oil,sunflower oil,motorvycle oil, factory machine cooking oil ,lube oil,essential oil,coconut oil,vegetable oil,olive oil,palm oil,peanut oil,engine oil,soybean oil,sunflower oil,motorvycle oil, factory machine lubricating oil, fragrant oil and so on,,which can finish bottle washing,filling and capping automatically.

♦ Number of filling valves: 4 - 16 heads;

♦ Production capacity: 400 bottles/hour - 500 bottles/hour;

♦ Suitable filling container size: Φ - Φ 165 mm or 65 bottles of 65-140 mm, height 180-360 mm;

♦ Host power:1.5 KW;

♦ Power voltage: three-phase four-wire 380v power supply;

♦ Air source: 0.4-0.8MPa 0.1m3 / min;

♦ Host profile size: 1500mm * 1200mm * 2000mm.

♦ High efficiency and low cost.

♦ Fully automatic control and high hygienci design.

♦ Excellent and stable priduct quality.

♦ Asving work space and manpower for users.

♦ Easy maintenance and high safety standard.

♦Full automatic multiple filling.

♦Fluent movements and easy operation.

♦The oil pipeline is made from theSUS304 .

♦It equiped with Sanitary ball valve.

♦The filling valve is special processing and it no drip.

♦The filling head can be changed with different size ,Therefore,it is suitable for filling different containers .

♦It can be connected to other equipment into a production line, Thus achieve full automatic.

♦The filling valve can rise and fall freely and is suitable for bottles of different heights.

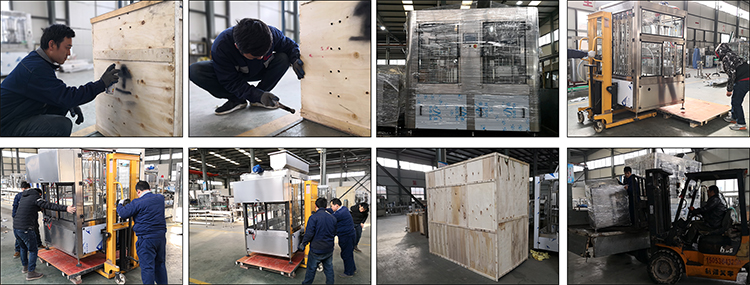

1.As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

2.Logistics: All machines will be sent by Shipping Logistics or Air Logistics, if you need other kind of transportation, please inform us in advance.

3.Delivery time: Shipped in 10-30 days after payment.

| 01 Found in 20 12,we are a hi-tech designing and manufacturing enterprise | 02 We have a serise of packaging machine that meets all your requirements | 03 we own a factory ourselves that assure the quality we manufactured |

| 04 OEM&ODM projects are both available | 05 We support the trade assurance service | 06 We have one year warranty of the spare parts,free of charge |

We have at least 5 times customer visited to our factory every month.

No matter what kind of bottle you need to packaging with filler or capper and so on,the machine can be provided to you to fit your need.

Q: Are you factory or trading company?

A:We are a professional manufacturer engaged in the research, development, production, sale and service of Bottle washing machine; Filling machine; Sealing machine; Labeling machine; Water treatment machine. Welcome to visit our factory!

Q: What is the term of payment ?

A: We accept T/T, Western Union, MoneyGram, L/C.

Q:When can I get the quotation?

A:We usually quote within 24 hours after we get your inquiry.We look forward to your inquiry

Q: Do you make test before shipment?

A: We always test machine fully and make sure it works smoothly before shipment.

Q: What's the MOQ?

A: There is no MOQ , welcome to order.

Q: What kind of package for shipping?

A:As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.