Applications

Universal application – the capping machines serves ANY type of closure and package.

Features

* Precise capping force, number of revolutions and head rotation speed.

* Adjusted head setting angle.

* Fast and easy change of settings and formats into capping a new product.

* Productivity: ~ 40 pcs./min.

Details Images

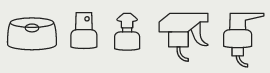

Universal application:

Pumps triggers flip-tops etc.

Four capping rolls:

Very fast and simple changeover.

Controlled by servo motor:

Precise capping torque control, may be set from the HMI panel.

Electrical box:

1. Electrical componnents are used world-renowned brands. 2. Customers can also choose the appliance brand they want.

Our service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

WHAT INFORMATION SHOULD YOU SHARE TO US BEFORE CONSULTING THE MACHINE?

●Details of your bottles and caps,such as appearance, size, capacity,etc.

●Details of your liquid, such as viscosity, acid-base property,or is it easy to foaming?

●Production requirement

●The space size you reserved for our equipments

●Other special functions

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to VKPAK site

● The meaning of visiting supplier, because seeing is believing, VKPAK with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

SEE VKPAK HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 2 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF VKPAK!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Would like to know more about VKPAK equipments, feel free to send us an inquiry!