Automatic Round Bottle Labeling Machine

1-Applicable bottles

NP-RL Automatic round bottle labeling machine also called vertical labeling machine, it is application for labelling a range of round bottles,

2-Working process of round bottles labeling machine

- Manually put bottles on conveyor or using a automatic botte turntable

- And the bottles will be separated by bottle separator to keep the each bottle distance for guarantee the working stable

- All the action are control by PLC, Automatic sense the bottle and labels, automatic apply the labels on the two sides of the bottles. And machine with function, no bottle no labeling, automatic warning if no label or lack of labels

- After apply the labels on bottles, the label paste device will paste the labels to fasten the label on bottles.

- Then bottle go to next processing

3-Advantages

- Stable-Adapt Siemens PLC control and Panasonic servo motor Driven label for machine working stably and label accuracy. It is high performance and high efficiency.

- Easy Operation-The touch screen can be in English, Spanish, French, Russia and any other language. It is easy operation and can be connect with other machines for production packaging line.

- High precision-Accuracy from +-0.5-1mm.

- wide application range-Widely using the bottle diameter from 25mm to 120mm, bottle heigh 25mm. to 300mm,If customized height of 10mm-150mm,length of 15mm-300mm, please kindly ask us.

- High speed-Speed max can reach 150bottles per min subject to the label size and bottle size.

- Europe standard-The labeling machine is made according to CE standard, Taiwan technology.

4-Main Tech

| Model / technical parameters | NP-RL |

| Labeling speed (pcs/min) | 40-100 (relate to material and label size) |

| Labeling accuracy(mm) | ±1.0mm (material and label sizes are not counted in) |

| Label size(mm) | (L)20-280mm (H)30-144mm |

| Material size (mm) | Φ20-φ100mm (H)40-200mm |

| Roll inside(mm) | φ76mm |

| Roll outer diameter(mm) | Max:Φ350mm |

| Machine size (mm) | (L)2000*(W)850*(H)1450(mm) |

| Power supply | AC220V 50Hz/60Hz 1500W |

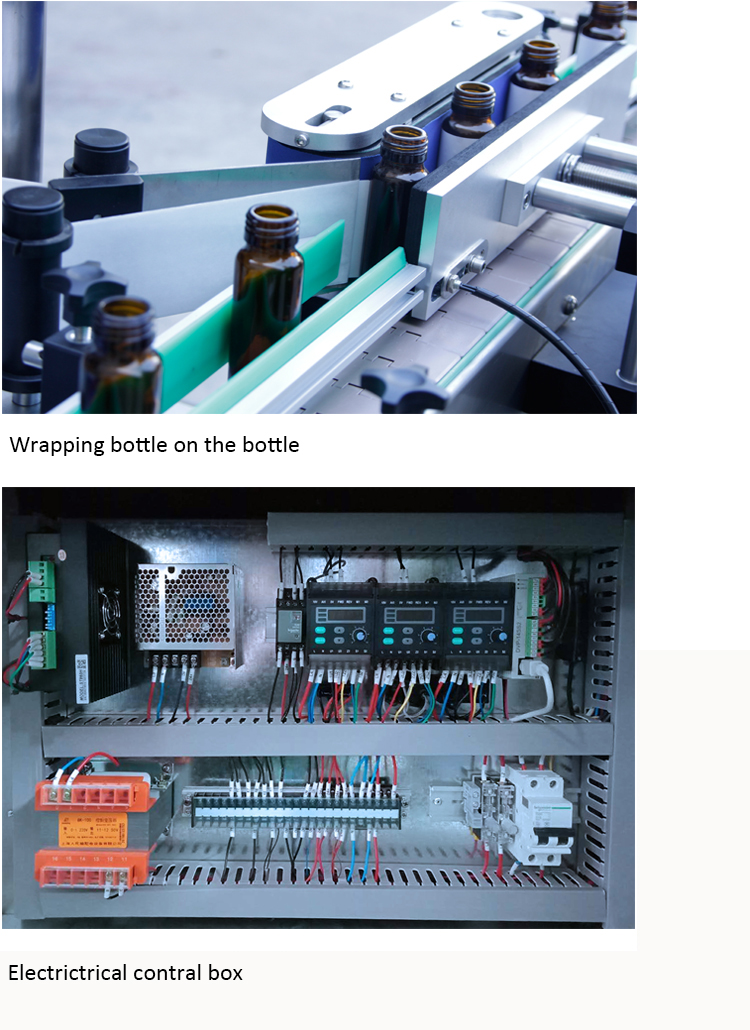

Detailed Images

| Configuration Parts of labeling machine | |||

| Item | Description | Quantity | Remark |

| 1 | PLC | 1 | Siemens Made In German |

| 2 | Touch Screen | 1 | Siemens Made In German |

| 3 | Transducer | 1 | Delta Made in Taiwan |

| 4 | DC24V Electrical Source | 1 | Delta Made In Taiwan |

| 5 | Checking Label Sensor | 1 | Leuze Made in German |

| 6 | Checking bottle Sensor | 1 | Keyence Made in Japan |

| 7 | Optical | 1 | Keyence Made in Japan |

| 8 | STEP MOTOR AND DRIVER | 1 | INVONATION SHENGZHEN |

| 9 | SWITCH | 1 | SCHNIDER FRANCE |

| 10 | Emergency Switch | 1 | SCHNIDER FRANCE |

| 1 year free spare parts | ||

| 1 | wearing belts | 2pcs |

| 2 | tools | 1 set |

Installation and Debugging

-- We will send engineers to carry out installation and debugging of the equipment in buyer's place if requested.

-- The cost for International double ways air tickets, accommodations, food and transportations, medical shall be paid by Buyer for the engineers.

-- The normal debugging term is 3-7days, and the buyer should pay US$80/day per engineer.

-- If customer do not require above, then customer need to be train in our factory. Before installation, the customer need read the operation manual firstly. Meanwhile, we will offer an operation video to customer.

Training

-- We offer machines training system; the customer can choose training in our factory or in customer workshop. The normal training days are 1-2 days.

Warranty

-- The sold machine will be guarantee in one year.

-- In the guarantee year, any spare parts broken due to supplier's quality issue the spare parts will be supplied free for customer, customer need to pay the freight cost if the parcel weight more than 500gram.

-- The easy wearing out spare parts are not in the warranty terms, such as O rings, belts which will be supplied with the machine for one year using.