The line adopts servo control piston filling technology , high precision , high speed,stable performance, fast dose adjustment features , is the 10-25L packagingline latest technology.

1. Filling Range: 1L-5L

2. Capacity: as customized

3. Filling Accuracy: 100mL t 5L

4. Production line machines: Filling machine, capping machine, labeling machine,carton-VKPAK machine, carton-packing machine and carton-sealing

Product introduction:

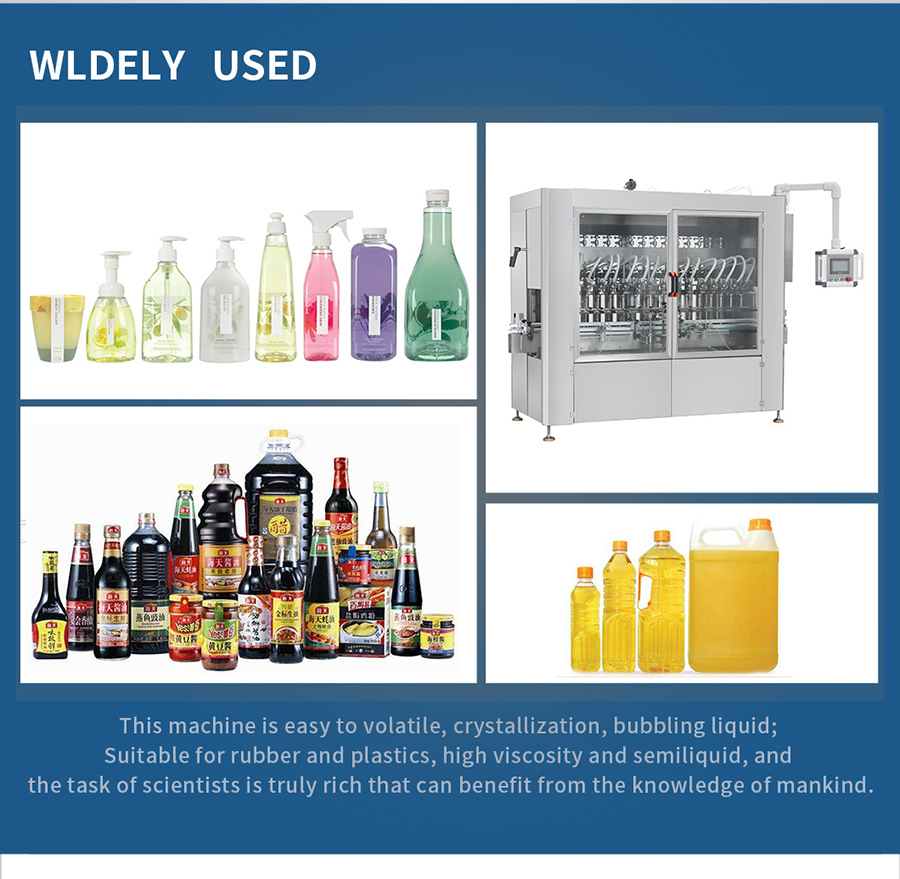

This is our newly developed filling machine . It has reached the international advanced level ,partial has exceeded the similar product . It is abroad , also certified by the world famous chemical magnate . This is a inline piston filling machine for cream and liquid ..It adopts PLC and touch screen control panel for control material . It is characterized by accurate measuring ,advanced structure ,stable operating ,low noise ,large adjusting range ,fast filling speed . It is also suitable for the filling of easy volatilization ,easy bubbly liquid strong corrosive liquid for rubber ,plastic,and high viscosity ,liquid ,semi-liquid . Operators adjust and meter figure in the touch screen control panel , also can adjust metering of each filling head . The external surface of this machine is made of excellent stainless steel . Good appearance , applied to GMP standard .

| Filling Nozzles | : | 1-16Nozzles |

| Production Capacity | : | 800 -5000Bottles Per Hour |

| Filling Volume | : | 100-500ml,100ml tp 1000ml |

| Power | : | 2000W, 220VAC |

| Accuracy | : | ±0.1% |

| Driven | : | Panasonic Servo Motor |

| Inerface | : | Schneider Touch Screen |

Machine Details:

NO.1

1.Quantitative filling, adjustment for one key on touch screen.

2.Adopt fast connect,easy to disassembly and wash, without dripping

3.Diving mode filling.

NO.2

1.High quality three - way valve, no dead Angle, no residue.

2.One key to clean residual material on cylinders.Different choices of filling Needles:

According to different customer requirements, we use a variety of different filling nozzles, used to fix to variety of viscosity, temperature and other conditions of the filling materials.

Different choices of pipes:

According to the customer's different choice, can be equipped with different materials of pipe, to meet the customer

variety of different liquid safe filling

Different choices of Piston rings:

The piston ring is resistant to wear. It has spring coil inside the piston ring. After minor wear, it has automatic

correction function,the cylinder won't happened leakage.

Food-grade piston rings

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Industrial-grade piston rings

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Different choice of Bottle unscrambler Machine

According to customers' requirements of different bottles and different production speed, we can use different kinds of automatic bottle unscrambler machines, and we can customize machines for customers to meet different production conditions.

Horizontal Bottle Unscrambler Machine

This machine is controlled by PLC and touch screen,operators can adjust all parameters on

the touch screen .frequency control the speed.

Operators only need to change the turntable

of the unscramble box in order to change the specification ,other parts can be adjusted.

The rotary table of the machine adopts variable frequency stepless speed regulation for rotary movement, so that the bottle enters the conveyor belt in sequence under the action of rotating tangential force, and is matched with the packaging production line to achieve the purpose of saving labor and improving production efficiency. This machine is used for power on, easy to operate.

After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.