hyaluronic acid vial bottle filling and capping machine suitable for batch production of antibiotics, biochemical medicine bottles, hair dye and other products requiring aluminum cover sealing, automatic rolling of caps.

Main technical parameters:

| Power supply | 380V 3 phase (could be customized) |

| Power consumption | 0.65KW |

| Suitable diameter | 22mm,24mm,30mm |

| Producing speed | 120 bottle/min |

| Filling accuracy | ≤±1% |

| Dimension | 1900×950×1450 mm |

Characteristic

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5. Optional Siemens Touch screen/PLC

6.No bottle no filling/plugging/capping

Our exclusive design of anti-pour bottle device, photoelectric sensor detection, when a horizontal bottle into the bottle mouth, can automatically protect and stop. It can save a large amount of raw material funds for the user, at the same time, can reduce the damage to the machine to the maximum extent, thus can prolong the machine's life well.

Picture reference : (The design of the machine could according to the request of the clients,it's not changeless, If you have purchase plan about the machine , please tell us your detailed request ,we will make a suitable solution accordingly)Best sale injection vial bottle filling and capping machine 300ml bottling equipment

2 Filling Nozzles

Features and Performance:Professional equipment eye drop filling and capping machine

1. Use peristaltic pump for filling system, which guarantee stable performance with high filling precision.

2. The filling head insert into the bottle for filling, no sprinkle

3. Emergency stop for no bottle and bottle falling situation.

4. Anti-fouling design for the table, which makes it easy to clean.

5. Quick assembling and disassembling design makes it easy to clean the peristaltic pump.

6. This machine can automatically complete bottle unscrambling, bottle conveying, filling, and plug feeding, plugging, cap feeding and camping.

7. New type capping system presents beautiful and reliable effect.

8. PLC and touch screen controlled, user-friendly design

9. Fully automatic from filling, cap feeding and cap closing in one machine

Application range Professional equipment eye drop filling and capping machine

This machine can roll 22mm, 24mm, 30 mm diameter antimicrobial molding, control glass bottle. Special specifications are available for rolling 50 ml / 100ml ml,500ml bottles or glass bottles that meet the requirements of the seal of the Silin bottle.

Layout : ( we could design the size according to your factory space)Quality assurance eye drop bottle filling capping machine

We offer a full range of packing and mixing machines which include emulsifying mixer, homogenizing machine, planetary mixer, tube filling and sealing machine, bottle filling and capping machine, adhesive filling and capping machine, automatic labeling machine and water treatment equipment. They are widely used in daily chemicals, pharmacy, medicines, adhesives and food industries.

All machines are designed to meet customers specific requirements (GMP for pharmacy factory) and can work smartly and smoothly at customer's site. We have creative design team to come up with the newest technology at times. Our products own ISO9001 qualification system and CE certificate.

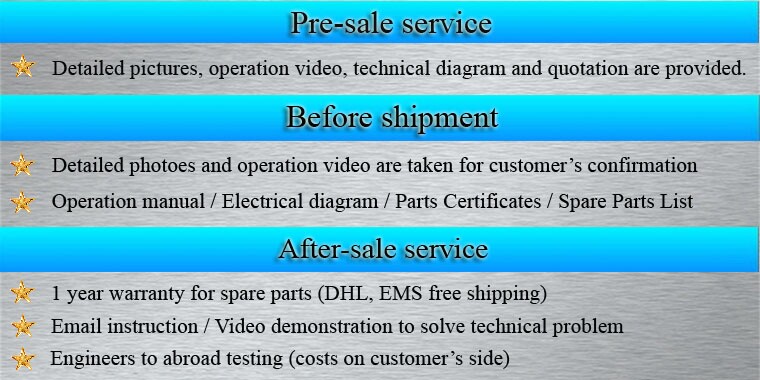

<1>What should I do if we are not able to operate the machine when we receive it?

Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer’s site to solve any problems.

<2>How could I get the spares on machines?

We will send extra sets of spares and accessories (such as sensors, heating bars, gaskets, O rings, coding letters). Non-artificial damaged spares will be sent freely and shipping free during 1 year’s warranty.

<3>How can I ensure that I get high-quality machine?

As a manufacturer, we have a strict supervision and control of every manufacturing step from raw materials purchasing, brands choosing to parts processing, assembling and testing.

<4>Is there any insurance to guarantee I will get the right machine I pay for?

We are an on-site check supplier from Alibaba. Trade Assurance provides quality protection, on-time shipment protection and 100% safe payment protection.

Send inquiry to us first , or contact us directly by email or wechat /whatsapp ,tell us your details about the machine

- Filling volume

-Filling speed

-The picture of the bottle with cap

-Tell us what material you want to filling , does it need ss316 material ?