lube oil filling machine, for 1-5L bottle chemical and oil packing, the machine combines filling and capping, it can fill the bottled cooking oil, jams, chili paste, sauces, and other high viscous liquids. The food and oil packaging production line can process different bottles holding less than 5L and functions as a complete production line with conveyors, labeling, filling, sealing, and packaging into cartons.

Filling Machine, Capping Machine, Labeling Machine motor oil filling line

Filling Machine, Capping Machine, Labeling Machine motor oil filling line

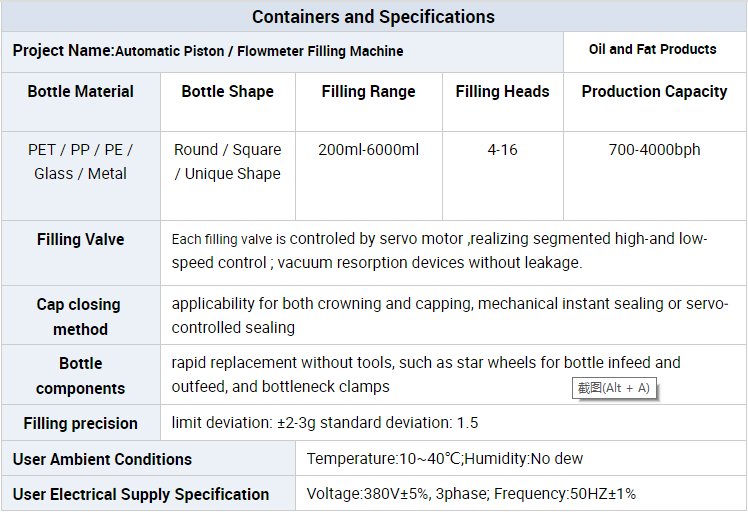

The main parameters | |

Filling speed | 800-4000bph |

Bottle diameter | Φ60-240mm |

Filling range | 100ml-6000ml |

Air pressure | 0.6~0.8 MPA |

Filling precision | less than 0.5% |

Power Source | 380V, 50HZ |

Details

1. Only two people (one operator, one assistant) are needed to operate this production line.

2. Oil filling machine is precise with a high qualified rate. Production capacity can be increased by up to 30%.

3. Double-sided self-adhesive labeling machine processes round and flat bottles.

4. Falling style packaging machine can process small quantities of heavier bottles that other machines can't.

5. The automatic carton opening and sealing machines are easy to operate and speed up production.

2. Oil filling machine is precise with a high qualified rate. Production capacity can be increased by up to 30%.

3. Double-sided self-adhesive labeling machine processes round and flat bottles.

4. Falling style packaging machine can process small quantities of heavier bottles that other machines can't.

5. The automatic carton opening and sealing machines are easy to operate and speed up production.

Company Introduction

The main products are liquid material filling machine as follows:

1. Carbonated drink filling machine.

2. Beer filling machine.

3. Juice filling machine.

4. 3/5 gallon water filling machine.

5. Oil/Cosmetic liquid/Shampoo/Detergent/Jam/Honey/Ketchup filling machine and so on.

6. Labeling machine and packaging machine.

Why Choose Us

1. Standardized workshop of total 10,000 square meters.

2. Advanced processing and testing equipment, like water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier & korea daewoo, ensure the precision of parts.

3. Before leaving the factory, the equipment shall be tested and operated for 24 hours to ensure the smooth flow of water pipeline and the stability of pneumatic, electrical and mechanical.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5. We have a number of international certification, national equipment certification, more than 20 invention patents and ISO9001:2001; CE certificate, SGS, COC, TUV and other certificates.

6. We have sufficient stock of spare parts to ensure that the equipment is delivered on time.

7. Our experienced engineers can design the produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

8. Have a professional after-sales team, can speak fluent English, help customers benefit in the shortest time.

Packing&Shipping

Our machine will be packed by wooden case, it is suitable for sea transportation.The machine will be fixed strongly in the container during for long way shipping.

FAQ

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer with more than ten years; we supply the factory price with top grade quality, and welcome to visit our factory.

A1: We are a manufacturer with more than ten years; we supply the factory price with top grade quality, and welcome to visit our factory.

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you machines with 2 year guarantee and have engineer can go overseas supply life-long technical support.

A2: We offer you machines with 2 year guarantee and have engineer can go overseas supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The deliver time is based on your order, for general about 1-3 month.

Q4: How can I install my machine when it arrives?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q5: How about the spare parts?

A5: We will offer you a spare parts list for your reference, and will provide all parts when you need them.