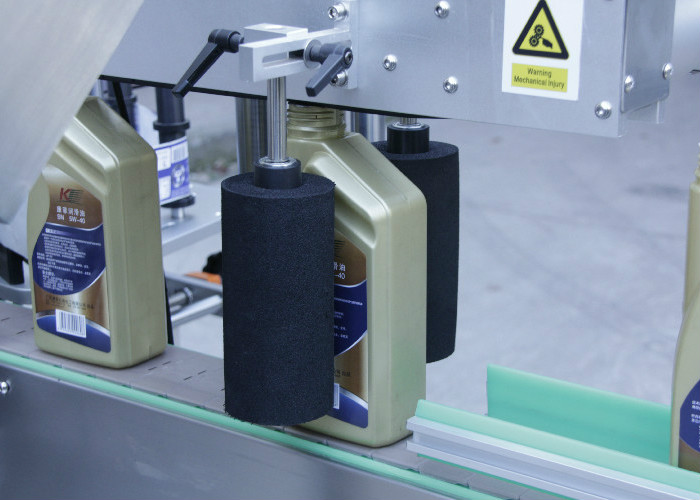

Automatic bottle labeling machine, vial labeling machine, bottle labeling machine widely used for different sizes of round products such as round bottles, cans, jars, cylinder in daily chemicals, food, beverages, medicine and other industries

Technician parameter of round bottle labeling

| 1 | Labeling accuracy | ±1mm (not including the label error) |

| 2 | Labeling speed | 30~2000bpm |

| 3 | Diameter&height of bottles | Diameter:φ25mm~φ120mm height:15mm~300mm |

| 4 | Label size | Length:20mm~290mm Width:15mm~300mm |

| 5 | The overall size of the machine | About 1800mm×800mm×1500mm(L×W×H) |

| 6 | Supply power | 220V/50HZ 110V/60HZ |

| 7 | N.W | 260Kg |

Packaging & Shipping

1.DELIVERY LEAD TIME:

15-20 WORKING DAYS FOR THE AUTOMATIC STICKER LABELING MACHINE AFTER RECEIVED DEPOSIT

2.TERMS OF PAYMENT:

BY 30% IN ANVANCED, THE BALANCE 70% BY T/T BEFORE SHIPMENT

3.PRICE VALID UNTIL:

15-20DAYS.

4.PACKING:

WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5.PORT OF SHIPMENT:

SHANGHAI PORT

FAQ

Q | A |

| 1. No electric | 1. Check the power switch. 2. Check the circuit breaker in the crate. 3. Check the fuse. |

| 2. No putout | 1. The input signal failure, check cable. 2. The system switch is off, put it on. |

| 3. Didn’t label | 1. The photoswitch sensitivity too strong or too weak, adjust the sensitivity. 2. Warning time too short or set 0, set it 1-3 seconds is appropriate. 3. Label tension is not enough. Adjust the tension. 4. The motor of labeling parts is not connected. Plugin the motor. |

| 4. Continuous sand labels | 1. The label sensor identification label, Teach the photoswitch. 2. Labels photo switch in the wrong place. Adjust the label photo switch location or label position, so that the detection point can detect labels. 3. Label photoelectric switch failure. Adjust or replace the labels photoelectric switch |

5. Labels couldn’t paste on the bottle | 1. Sand label too late, curtail the label position time. 2. Sand label too early, adds the label position time. 3. The label isn’t adhesive or the bottle isn’t clean. |

Our Services

1.WARRANTY

THE SELLER WARRANTY THE MACHINE FOR ONE YEAR, AND SUPPLY ONE YEAR FREE SPARE PARTS WITH THE MACHINE.

2.TERMS FOR INSTALLATIONS,STARTING-UP AND ADJUSTMENT.

THE SELLER SHOULD SEND ENGINEERS TO CARRY OUT INSTALLATION AND DEBUGGING OF THE EQUIPMENT IN BUYER’S PLACE IF REQUESTED. THE COST FOR INTERNATIONAL DOUBLE WAYS AIR TICKETS SHALL BE PAID BY BUYER FOR THE ENGINEER. BUYER SHALL

COOPERATE WITH SUPPLIER’S ENGINEER AND MAKE ALL THE INSTALLATION CONDITION READY TO WORK. SUCH AS”WATER, ELECTRICITY, RAW MATERIAL ETC.

3.OPERATION MANUAL

THE OPERATION MANUL WILL BE SHIPPED WITH THE GOODS AND IN ENGLISH VERSION.

Our company is a professional manufacturer and exporter that is concerned with the design development and production of vial labeling machine, water bottle labeling machine, filling and sealing machine, labeling machine, capping machine, automatic packaging machine etc.

We are located in shanghai city, with an advantageously geographical location and convenient transportation. We boast state-of-the-art automatic production lines, domestically advanced production technologies and complete testing equipment and quality systems. It gives us a broad development space. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our leading products include two part :

(1)Automatic bottle labeling machine, capping labeling package machine make it by our factory, not only save the cost, but also create great value for customers.

(2)The second part is the production of professional equipment, to provide whole plant planning, corollary equipment, after-sales and in providing one-stop service. we are committed to enable customers to buy the most cost-effective equipment, enjoy the best quality pre-sale and after-sale service.